Laminae Rigidae Laminatae e Panno Vitreo Epoxy (laminae EPGC)

Laminae Rigidae Laminatae e Panno Vitreo Epoxy seriei EPGC constant ex panno vitreo texto, resina epoxy thermosetante imbuta, sub alta temperatura et alta pressione laminata. Pannus vitreus texto carens alcali et copulatore silano tractandus est. Laminae seriales EPGC includunt EPGC201 (NMEMA G10), EPGC202 (NEMA FR4), EPGC203 (NEMA G11), EPGC204 (NEMA FR5), EPGC306 et EPGC308.

Laminae EPGC (classis thermalis: B~H), secundum IEC60893-3-2 productae. Hae laminae praeclaram firmitatem mechanicam habent (ratio retentionis firmitatis thermalis plus quam 50%) sub temperatura media vel statu thermali, necnon stabilem proprietatem electricam (resistentia insulationis post immersionem 1012Ω attingit) sub condicionibus humiditatis altae. Necnon maiorem tolerantiam tensionis / tensionem sustinentem (plus quam 35kV), parallelam laminationi. EPGC202, EPGC204 et EPGC306 etiam excellentem proprietatem retardationis flammae habent. Laminae etiam detectionem substantiarum toxicarum et periculosarum (cum Relatione RoHS) superaverunt.

Adhibetur ut partes structurales insulationis in motoribus electricis Classis BH, apparatu electrico, qui requisita resistentiae flammae habent vel non, vel aliis applicationibus.

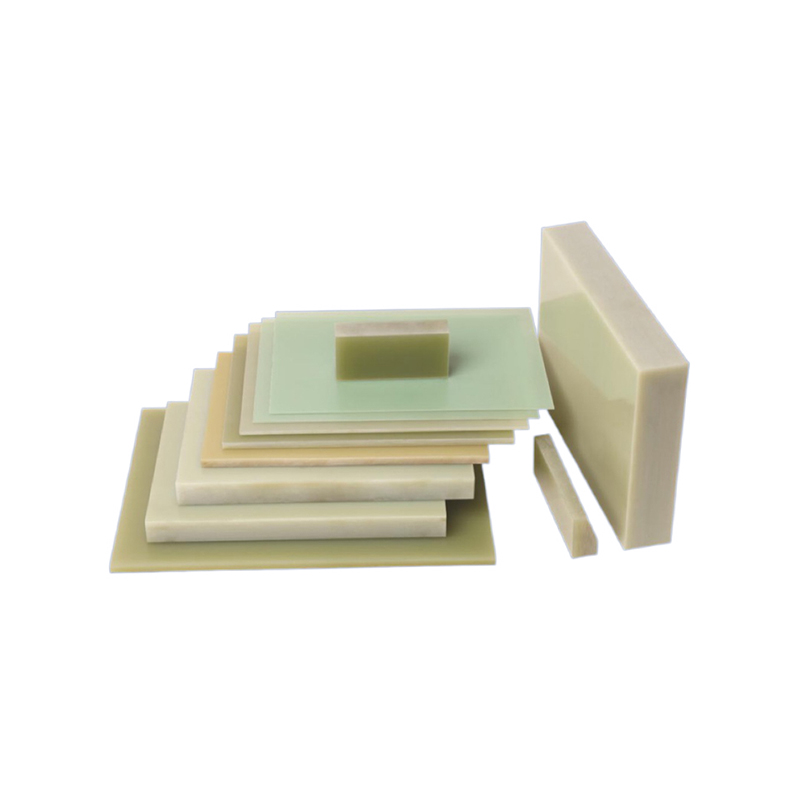

Crassitudo praesto:0.30mm~200mm

Magnitudo chartae praesto:

1500mm*3000mm, 1220mm*3000mm, 1020mm*3000mm, 1020mm*2440mm, 1220mm*2440mm, 1500mm*2440mm, 1000mm*2000mm, 1200mm*2000mm, et aliae magnitudines pactae.

Classificatio et Genus Chartarum Epgc

| Nomen typi | Applicatio et proprietas | Classis thermalis | |||

| D&F | GB/IEC | NEMA | alii | ||

| DF201 | EPGC201 | G10 | Hgw 2372 | Ad machinas, apparatum electricum et electrones. Magna robore sub temperatura media, excellenti resistentia arcus et PTI et CTI altiore praedita. | B 130℃ |

| DF202 | EPGC202 | FR-4 | Hgw 2372.1, F881 | Similis EPGC201, habens declaratum retardantem igni. | B 130℃ |

| DF202A | --- | --- | --- | Similis DF202, sed cum maiori robore mechanico. | B 130℃ |

| DF203 | EPGC203 | G11 | Hgw2372.4 | Ad apparatum mechanicum, electricum et electrones. Summa robore sub temperatura media praeditum. | F 155℃ |

| DF204 | EPGC204 | FR-5 | Hgw 2372.2 | Similis DF203, habens declaratum retardantem igni. | F 155℃ |

| DF306 | EPGC306 | --- | DF336 | Similis DF203, praestans excellentem resistentiam flammae, resistentiam arcus et PTI altiore. | F 155℃ |

| DF306A | --- | --- | --- | Similis DF306, sed maiori robore mechanico praeditus. | F 155℃ |

| DF308 | EPGC308 | --- | --- | Similis DF203, sed cum meliore stabilitate termica. | Alta temperatura 180°C |

Requisita Technica

Aspectus

Superficies laminae plana et levis esse debet, carens bullis aeris, rugis aut fissuris, et satis carens aliis imperfectionibus parvis, ut scalpturis, foveis, etc. Margo laminae mundus et liber a delaminatione et fissuris erit. Color substantialiter uniformis erit, sed paucae maculae licitae sunt.

Crassitudo nominalis et tolerantiaUnitas: mm

| Crassitudo nominalis | Deviatio | Crassitudo niminalis | Deviatio |

| 0.5,0.6 0.8,1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.15 +/-0.18 +/-0.21 +/-0.25 +/-0.30 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.85 +/-2.10 +/-2.45 +/-2.60 +/-2.80 |

| Adnotationes: Pro laminis crassitudinis non nominalis in hac Tabula non enumeratis, deviatio permissa eadem erit ac crassitudinis proximae maioris. | |||

Deflexio Flexionis pro LaminisUnitas: mm

| Crassitudo | Deflexio Flexionis |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 |

Processus mechanicus:

Laminae liberae esse debent a rimis et fragmentis cum talis machinatio ut serratio, perforatio, tornio et fresatura adhibetur.

Proprietates Physicae, Mechanicae et Dielectricae

| Non. | Proprietates | Unitas | EPGC201 | EPGC202 | EPGC203 | ||||

| Valor normalis | Valor typicus | Valor normalis | Valor typicus | Valor normalis | Valor typicus | ||||

| 1 | Absorptio aquae (lamina 2mm) | mg | ≤20 | 8 | ≤20 | 9 | ≤20 | 9 | |

| 2 | Robur flexionale | In statu normali | MPa | ≥340 | 460 | ≥340 | quingenti | ≥340 | 450 |

| (Longitudinalmente) | 155℃ +/- 2℃ | --- | --- | --- | --- | ≥170 | 240 | ||

| 3 | Robur impacti, parallelum laminationibus (Charpy, incisura) | kJ/m² | ≥33 | 53 | ≥33 | 51 | ≥33 | 50 | |

| 4 | Robur electricum, perpendiculare ad laminationes (in oleo transformatoris ad 90℃ +/- 2℃) | kV/mm | ≥11.8 | 17 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Robur electricum, parallelum laminationibus (in oleo transformatoris ad 90℃ +/- 2℃) | kV | ≥35 | 48 | ≥35 | 45 | ≥35 | 45 | |

| 6 | Factor dissipationis dielectricae (1MHz) | --- | ≤0.04 | 0.02 | ≤0.04 | 0.02 | ≤0.04 | 0.021 | |

| 7 | Constans dielectrica (1MHz) | --- | ≤5.5 | 4.8 | ≤5.5 | 4.7 | ≤5.5 | 4.7 | |

| 8 | Resistentia arcus | s | --- | --- | --- | CLXXXII | --- | CLXXXII | |

| 9 | Resistentia vestigationis probata (PTI) | V | --- | --- | --- | DC | --- | DC | |

| 10 | Resistentia insulationis post immersionem in aqua | MΩ | ≥5.0x10⁴ | 2.1 x 107 | ≥5.0x10⁴ | 1.5 x 106 | ≥5.0x10⁴ | 1.1 x 107 | |

| 11 | Inflammabilitas | Gradus | --- | --- | V-0 | V-0 | --- | --- | |

| 12 | Index Temperaturae (TI) | --- | ≥130 | ≥130 | ≥155 | ||||

| Non. | Proprietates | Unitas | EPGC204 | EPGC306 | EPGC308 | ||||

| Valor normalis | Valor typicus | Valor normalis | Valor typicus | Valor normalis | Valor typicus | ||||

| 1 | Absorptio aquae (2 mm) | mg | ≤20 | 11 | ≤20 | 8 | ≤20 | 9 | |

| 2 | Robur flexionale | In statu normali | MPa | ≥340 | 480 | ≥340 | 460 | ≥340 | quingenti |

| (Longitudinalmente) | 155℃ +/- 2℃ | ≥170 | 260 | ≥170 | 280 | --- | 270 | ||

| 3 | Robur impacti, parallelum laminationibus (Charpy, incisura) | kJ/m² | ≥33 | 51 | ≥33 | 53 | ≥33 | 52 | |

| 4 | Robur electricum, perpendiculare ad laminationes (in oleo transformatoris ad 90℃ +/- 2℃) | kV/mm | ≥11.8 | 16 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Robur electricum, parallelum laminationibus (in oleo transformatoris ad 90℃ +/- 2℃) | kV | ≥35 | 45 | ≥35 | 48 | ≥35 | 45 | |

| 6 | Factor dissipationis dielectricae (1MHz) | --- | ≤0.04 | 0.018 | ≤0.04 | 0.02 | ≤0.04 | 0.02 | |

| 7 | Constans dielectrica (1MHz) | --- | ≤5.5 | 4.7 | ≤5.5 | 4.8 | ≤5.5 | 4.7 | |

| 8 | Resistentia arcus | s | --- | --- | --- | CLXXXII | --- | --- | |

| 9 | Resistentia vestigationis probata (PTI) | V | --- | --- | --- | DC | --- | --- | |

| 10 | Resistentia insulationis post immersionem in aqua | MΩ | ≥5.0x10⁴ | 3.8 × 106 | ≥5.0x10⁴ | 1.8 x 107 | ≥5.0x10⁴ | 7.1 x 106 | |

| 11 | Inflammabilitas | Gradus | V-0 | V-0 | V-0 | V-0 | --- | --- | |

| 12 | Index Temperaturae (TI) | --- | ≥155 | ≥155 | ≥180 | ||||

Impacatio et Repositio

Laminae in loco ubi temperatura non superat 40°C reponendae sunt, et horizontaliter in lamina alta 50mm vel plus ponendae. Ab igne, calore (apparatu calefaciente) et sole directo arceantur. Vita laminarum repositionis est 18 menses a die quo officina egressa est. Si spatium repositionis plus quam 18 menses est, productum etiam post probationem ad qualificationem adhiberi potest.

Adnotationes et Cautiones pro Applicatione

1 Machinatio cum JB/Z141-1979 congruere debet,Methodi machinationis productorum laminatorum insulationis, quia laminae differentiam inherentem attributorum a metallo habent.

2 Celeritas magna et profunditas sectionis parva adhibendae sunt in machinatione propter imbecillam conductivitatem thermalem laminarum.

3 Machinatio et sectio huius producti multum pulveris et fumi emittent. Mensurae idoneae adhibendae sunt ut gradus pulveris intra limites acceptabiles maneant per operationes. Ventilatio localis extractionis et usus idoneorum tegumentorum pulveris/particularum commendatur.

4 Laminae post machinationem humiditati obnoxiae sunt; stratum vernis insulantis commendatur.

Instrumenta Productionis

Fasciculus pro chartis EPGC