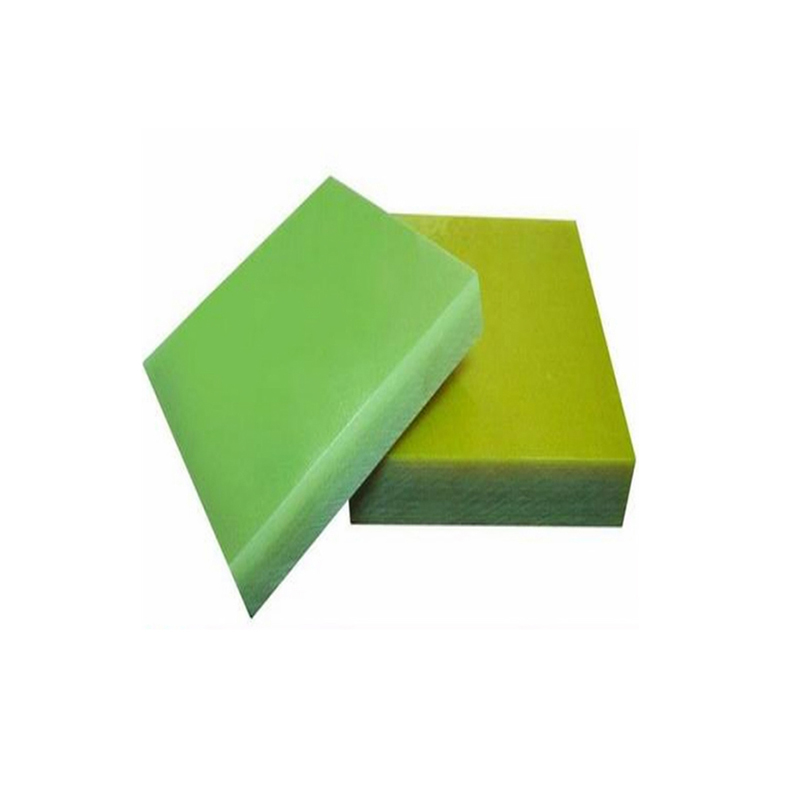

Epoxy vitreum Cloth Rigidum Laminated rudentis (EPGC iaculis)

EPGC series epoxy Pannum vitreum rigidum laminatum Sheet constat e panno vitreo contexto cum resina thermosente epoxy imbuta, laminata sub caliditate et alta pressione.Pannus vitreus textilis alcali gratis tractabitur a silano coniugatore.EPGC Vide chartas includunt EPGC201 (NMEMA G10), EPGC202(NEMA FR4), EPGC203(NEMA G11), EPGC204 (NEMA FR5), EPGC306 et EPGC308.

Schedae EPGC (classis scelerisque: B~H), productae ut per IEC60893-3-2.Hae schedae praestantem vim mechanicam habent (specialis vis retentionis status scelerisque super 50% attingere potest) sub media temperie vel in statu scelerisque, ac etiam proprietas electrica stabilis (resistentia insulationis post immersionem pervenit 1012Ω) in alta humiditate conditionis.Ac etiam cum superiori intentione patientiam / intentioni (supra 35kV) parallela laminationi resistere.EPGC202, EPGC204 et EPGC306 etiam res egregias flammam retardant.Etiam schedae deprehensio substantia toxica et ancipitia transierunt (cum RoHS Report).

Usus est ut partes structurarum insulationum in Class BH instrumentorum electrica motorum,electricorum, quae flammae resistentiae requiruntur vel non, vel aliae applicationes.

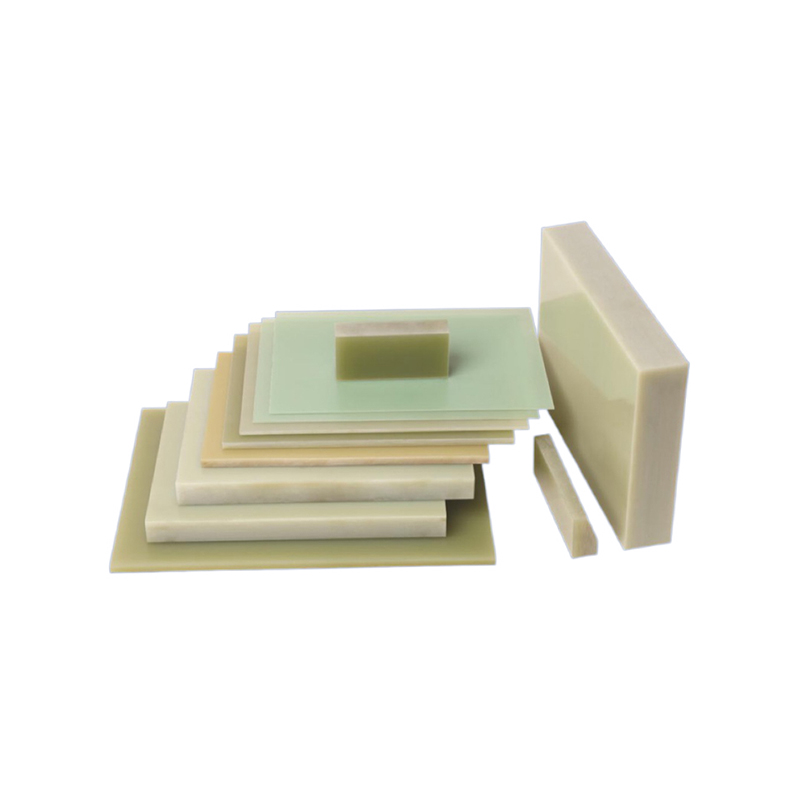

Praesto crassitudo;0.30mm~200mm

Available sheet size:

1500mm*3000mm、1220mm*3000mm、1020mm*3000mm、1020mm*2440mm、1220mm*2440mm、 1500mm*2440mm、1000mm*2000mm、1200mm*2000mm et alias moles agebant.

Classificationem et genus Epgc rudentis

| Typus nomen eius | Application & pluma | Scelerisque class | |||

| D&F | GB/IEC | NEMA | alii | ||

| DF201 | EPGC201 | G10 | Hgw 2372 | Pro machina, instrumento electrico et electrons.Cum vi alta sub temperatura media, resistentia arcui excellenti et altiori PTI et CTI | B 130℃ |

| DF202 | EPGC202 | FR-4 | Hgw 2372.1,F881 | Similia sunt EPGC201, habendo dicta flamma retardant. | B 130℃ |

| DF202A | --- | --- | --- | Similes DF202, sed cum superioribus viribus mechanicis. | B 130℃ |

| DF203 | EPGC203 | G11 | Hgw2372.4 | Nam mechanica, instrumenta electrica et electrons.Cum summa vi media temperatus | F 155℃ |

| DF204 | EPGC204 | FR-5 | Hgw 2372.2 | Similes sunt DF203, possidentes dicta flamma retardant. | F 155℃ |

| DF306 | EPGC306 | --- | DF336 | Similes DF203, resistentia flammae egregiae possidentes, resistentia arcui et PTI altius. | F 155℃ |

| DF306A | --- | --- | --- | Similes DF306, sed superiores vires mechanicas possidentes. | F 155℃ |

| DF308 | EPGC308 | --- | --- | Similes DF203, sed meliore stabilitate scelerisque. | H 180℃ |

Technical Requisita

Aspectus

Superficies schedae erit plana et levis, bullarum aeris libera, rugae vel rimas et alias imperfectiones parvas rationabiliter immunes, sicut exasperat, dents, etc. Ora schedae luculenta erit, et rimas et rimas expers erit.Color substantialiter uniformis erit, sed maculae paucae licitae sunt.

Crassitudo et tolerantia nominalUnitas: mm

| Crassitudine nominatim | Deviatio | Niminal crassities | Deviatio |

| 0.5,0.6 0.8,1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.15 +/-0.18 +/-0.21 +/-0.25 +/-0.30 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.85 +/-2.10 +/-2.45 +/-2.60 +/-2.80 |

| Animadversiones: Nam chartae crassitudinis non-nominatae in hac Tabula non recensentur, licita declinatio eadem erit ac majoris crassitudinis sequentis. | |||

Inflexio deflexio pro rudentisUnitas: mm

| Crassitudo | inclinatio Deflexionis |

| 3.0~6.0 6.0~8.0 8.0 | ≤10 ≤8 ≤6 |

Mechanica processus:

Plagulae a rimis et micis immunes erunt, ubi haec machinatio ad secandum, palaestra, lascivum et molarium applicatur.

Physica, Mechanica Et Dielectric Properties

| Nec. | Properties | Unitas | EPGC201 | EPGC202 | EPGC203 | ||||

| Vexillum valorem | Typical valorem | Vexillum valorem | Typical valorem | Vexillum valorem | Typical valorem | ||||

| 1 | Aquae effusio(2mm sheet) | mg | ≤20 | 8 | ≤20 | 9 | ≤20 | 9 | |

| 2 | Roboris flexus | In normalis conditio | MPa | ≥340 | 460 | ≥340 | 500 | ≥340 | 450 |

| (Longwise) | 155℃+/-2℃ | --- | --- | --- | --- | ≥170 | 240 | ||

| 3 | Impact vires, parallelae laminationum (Charpy, incisura) | kJ/m2 | ≥33 | 53 | ≥33 | 51 | ≥33 | 50 | |

| 4 | Vires electricae, laminationum perpendiculares (in transmutatoriis olei ad 90℃+/-2℃) | kV/mm | ≥11.8 | 17 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Vires electricae, laminationibus parallelis (in commutatore olei ad 90℃+/-2℃) | kV | ≥35 | 48 | ≥35 | 45 | ≥35 | 45 | |

| 6 | Dielectrica dissipatio factor(1MHz) | --- | ≤0.04 | 0.02 | ≤0.04 | 0.02 | ≤0.04 | 0.018 | |

| 7 | Dielectric constant(1MHz) | --- | ≤5.5 | 4.8 | ≤5.5 | 4.7 | ≤5.5 | 4.7 | |

| 8 | Arcus resistentia | s | --- | --- | --- | 182 | --- | 182 | |

| 9 | Probatur tracking resistentia (PTI | V | --- | --- | --- | 600 | --- | 600 | |

| 10 | Nulla resistentia post immersionem in aqua | MΩ | ≥5.0x104 | 2.1 x107 | ≥5.0x104 | 1.5 x106 | ≥5.0x104 | 1.1 x107 | |

| 11 | Flammability | Gradus | --- | --- | V-0 | V-0 | --- | --- | |

| 12 | Index Caloris(TI) | --- | ≥130 | ≥130 | ≥155 | ||||

| Nec. | Properties | Unitas | EPGC204 | EPGC306 | EPGC308 | ||||

| Vexillum valorem | Typical valorem | Vexillum valorem | Typical valorem | Vexillum valorem | Typical valorem | ||||

| 1 | Aquae effusio(2mm) | mg | ≤20 | 11 | ≤20 | 8 | ≤20 | 9 | |

| 2 | Roboris flexus | In normalis conditio | MPa | ≥340 | 480 | ≥340 | 460 | ≥340 | 500 |

| (Longwise) | 155℃+/-2℃ | ≥170 | 260 | ≥170 | 280 | --- | 270 | ||

| 3 | Impact vires, parallelae laminationum (Charpy, incisura) | kJ/m2 | ≥33 | 51 | ≥33 | 53 | ≥33 | 52 | |

| 4 | Vires electricae, laminationum perpendiculares (in transmutatoriis olei ad 90℃+/-2℃) | kV/mm | ≥11.8 | 16 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Vires electricae, laminationibus parallelis (in commutatore olei ad 90℃+/-2℃) | kV | ≥35 | 45 | ≥35 | 48 | ≥35 | 45 | |

| 6 | Dielectrica dissipatio factor(1MHz) | --- | ≤0.04 | 0.018 | ≤0.04 | 0.02 | ≤0.04 | 0.02 | |

| 7 | Dielectric constant(1MHz) | --- | ≤5.5 | 4.7 | ≤5.5 | 4.8 | ≤5.5 | 4.7 | |

| 8 | Arcus resistentia | s | --- | --- | --- | 182 | --- | --- | |

| 9 | Probatur tracking resistentia (PTI | V | --- | --- | --- | 600 | --- | --- | |

| 10 | Nulla resistentia post immersionem in aqua | MΩ | ≥5.0x104 | 3.8 x106 | ≥5.0x104 | 1.8 x107 | ≥5.0x104 | 7.1 x106 | |

| 11 | Flammability | Gradus | V-0 | V-0 | V-0 | V-0 | --- | --- | |

| 12 | Index Caloris(TI) | --- | ≥155 | ≥155 | ≥180 | ||||

Stipare et at

Schedae recondantur in loco ubi temperatura non est altior quam 40℃, et in strato cum altitudine 50mm vel supra horizontaliter ponatur.Abstine ab igne, calorem (heating apparatus) et soles dirige.Vita chartarum reposita est duodeviginti mensium a die omissionis officinas.Si spatium repositionis super duodeviginti mensium latum est, productus etiam post probationem idoneus adhiberi potest.

Dicta et cautiones ad Applicationem

I Machinatio cum JB/Z141-1979 paruerit;Machinandi modos products laminated veliteo quod schedae differentiam a metallo attributam habent.

2 Magna velocitas et profunditas parva secanda applicabitur cum machinatio propter schedas debiles conductas scelerisque.

3 Machining and cutting this product will release much dust and smoke.Apta consilia adhibenda sunt ut gradus pulvisculi intra limites acceptabiles in operationibus sint.Loci evacuationes exhauriunt et aptae pulvis/particulae larvarum utentes monentur.

4 Linteae umori posteaquam machinatae subiectae sunt, tunica insulating evanescenti commendatur.

Productio Equipment

In Package enim EPGC rudentis